|

|

Power Plant

Projects

| REFERENCE PROJECT |

|

Customer:

Public Power Corporation S.A.

Aghios Dimitrios Power Plant, Greece

Project:

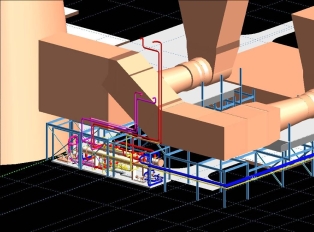

Upgrade of steam turbines of units III and IV, Flue Gas Heat Recovery System, Energico Oy jointly with Power Machines, Russia

Consortium Siemens- Power Machines

Order:

September 2006

Take-Over:

Unit IV January 2009,

Unit III May 2009

|

|

Energico's Services:

Complete delivery of Flue Gas Heat Recovery System excluding civil works

- main contractor functions

- process, layout, piping and E+C&I engineering of FGHR system

- erection and supervision

- commissioning and trial run

|

|

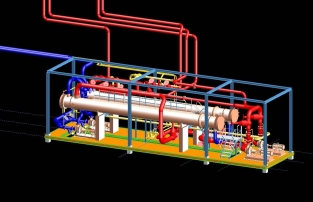

Energico's Scope of Supplies:

- heat exchangers

- expansion tank and pressurizing system

- hot water and condensate pumps

- piping and heat insulation

- shut-off and control valves

- electrification and instrumentation

- distributed control system |

| Main Data of Flue Gas Heat Recovery System per Unit: |

Flue Gas: |

MCR |

| - Mass flow per heat exchanger (2 x 50%) |

332 kg/s |

| - Volume flow, wet |

520 m³/s |

| - Volume flow, wet |

278 Nm³/s |

| - Volume flow, dry |

205 Nm³/s |

| - Temperature upstream heater, normal/design |

190/232°C |

| - Temperature downstream heater |

130°C |

| |

|

Hot Water:

|

|

| - Mass flow per FGHR unit |

83,7 kg/s |

| - Temperature at the inlet of the heater |

90°C |

| - Temperature at the outlet of the heater |

158°C |

| - Pressure at the inlet of the heater, operation/design |

20/34 bar(g) |

| |

|

Produced Useful Thermal Power:

|

|

| - From the two flue gas lines |

45 MW |

| Additional power of steam turbine |

6,7 MW |

| |

|

« Back |